Features:

- ± 3 V or better, ± 1 V with the optional external feedback system

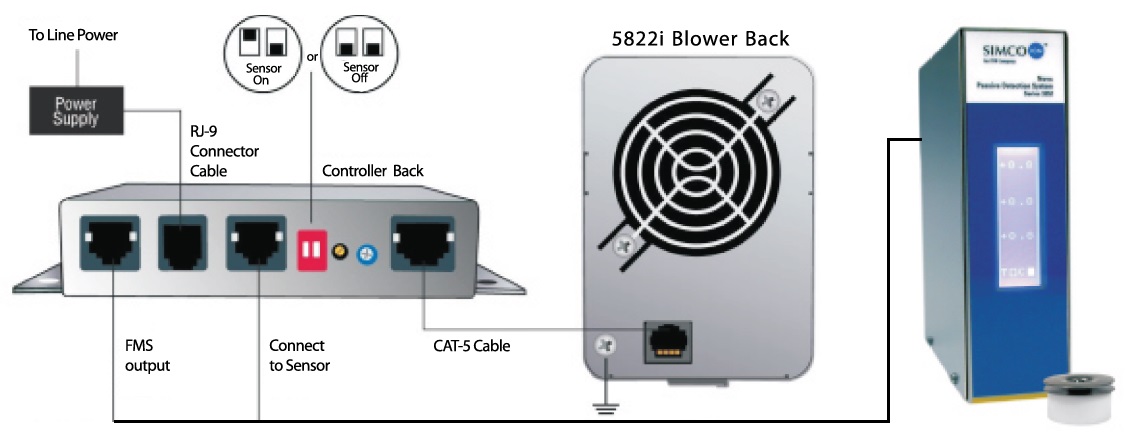

- Facility Monitoring System (FMS) connection and audible alarm

- Separate control box

- Cleanliness rated at ISO 14644-1 Class 4

Benefits:

- Provides the best ESD critical environment protection available for maximizing yields

- Faster response to ionization failure with notification through tool or FMS

- Allows the blower to be situated close to the target area for fast electrostatic discharge

- Designed for use in environment with a controlled level of contamination

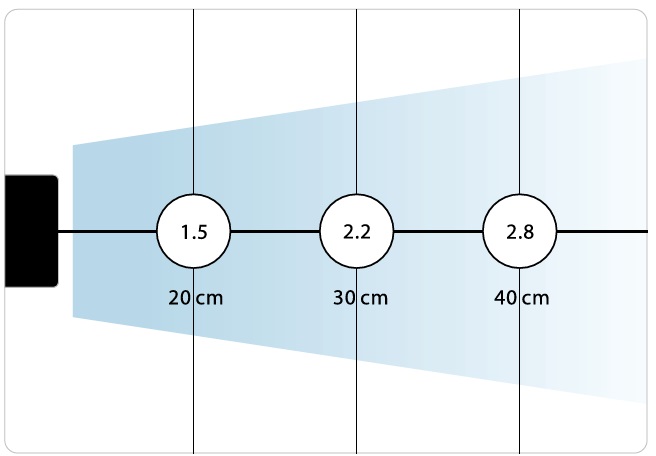

Typical Decay Time (sec)

Specifications:

| 5822i |

|

| Input Voltage | 24 VDC, 1 A max, External Power Supply (100 - 240 VAC, 50/60 Hz) |

| Decay Time | < 2.5 s @ (1000 V to 100 V, 30cm) |

| Balance | <±3 V typ. @ (30 cm, without external sensor); <±1 V typ. @ (30 cm, with external sensor) |

| Technology | Steady-state DC |

| Emitter | Tungsten Alloy; Optional - Machined Titanium |

| Cleanroom Class | ISO 14644-1 Class 4 |

| Controls | Balance adjust; Sensor gain adjust; Fan Slow/Off/Fast speed; Fan adjustment at "Slow" position; Sensor Mode DIP switch |

| Indicators | Control Box : Power - Green; Alarm - Red |

| Airflow (m3/min) | 0.58 (typ) |

| Audible Noise | < 56 dB @ 30cm |

| Operating Env. | 10 - 35ºC, 30 - 65% RH (non-condensing), ≤ ISO 14644-1 Class 7 or better |

| Mounting | 2 mounting screw holes 3.05cm apart on bottom of blower |

| Enclosure | Stainless Steel |

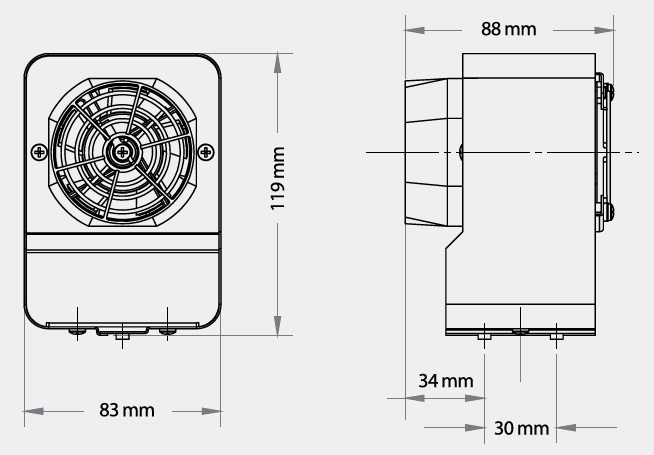

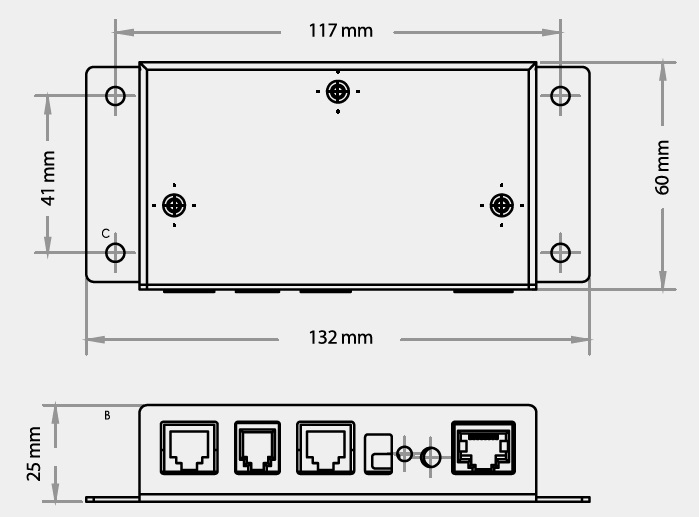

| Dimensions | Blower : 11.5H x 8.3W x 6.1D cm; Control Box : 2.5H x 13.2W x 6.0D cm |

| Weight | Blower : 0.51kg; Control Box : 0.25kg |

| Certifications |  |

Optional Feedback

The Model 5822i ionizer's optional external feed back sensor operates with the Novx Process Monitor 7000, Novx Passive Detection System 3352 and Novx Active Detection System 3362 to detect and automatically correct the balance. With the antenna placed at the target area, feedback is sent to the Model 5822i blower's internal control system. This ensures the target maintained at± 1 V or better balance at all times, no matter what environmental variables exist.

Directed Airflow

The collimator fits over the air outlet of the blower and directs ionized air straight to the target, so that the blower can be placed further away from the target with continued excellent discharge times and good performance at extended distances. This faster, directed airflow method improves ion and static elimination, significantly minimizing ion recombination.