Simco-Ion’s Model 5511, along with digital controllers Model 5580 or 5520, are designed to provide uniform ionization throughout the entire cleanroom area.. The system enables either centralized control of individual emitters through bi-directional communication between the Model 5511 and 5580/5520 controllers, or direct field programmability of the ceiling emitters with the Model 5570 handheld infrared (IR) remote control.

Digital technology allows the flexibility to control and address the operational settings of the Model 5511 system including alarm sensitivity, ion output (down to percentage levels), ion pulse timing, and polling frequency. The Model 5511 offers flexible settings to fit any environment—any specification.

The 5511 digital ceiling emitter system has specifically proved its success in addressing Current Good Manufacturing Practices (CGMP) regarding contamination control by the FDA. In addition to a reduction in yield losses, the 5511 can improve the quality and safety of products produced by life science (medical device, pharmaceutical and biotech) manufacturers. The 5511 ceiling emitter system can be the solution in meeting the FDA’s Quality System Requirement for contamination control.

Features:

- ISO 1 Cleanliness Design Traceability

- Bi-directional infrared remote control with alphanumeric LCD display for emitter adjustment

- Available with single crystal silicon emitter points

-

Pulse off-times separate positive and negative ion delivery with less recombination

- Integrates with 5585 AeroBars on the same controller

- Addressable emitters

- Pulse polarity synchronization

Benefits:

- Insures integrity of components used in life science CGMP manufacturing

- Effortless calibration of individual emitter operating ion balance, timing and ion output at point of use in real-time

- Semiconductor industry standard, ultra-clean, silicon wafer compatible emitter point material

- Extends emitter point cleaning intervals and life, due to reduced duty cycle

- Allows customized room system for any environmental or tool need

- Allows fast identification in case of alarm

- Optimizes ion delivery, reducing recombination in adjacent areas

Specifications

| Input Voltage | 24 VAC, 50/60 Hz, 1W (typ) |

| Output Voltage | 0-20 kVDC, ±10% each polarity; pos/neg output levels adjusted globally or individually at controller or locally at each emitter with the 5570 |

| Output Current | 20 microamps, current and voltage limited to eliminate shock hazard |

| Control Signal | Output levels and timing are adjusted with the 5570 remote control or with the 5520/5580 controller RS-485 connection |

| Connectors | Telephone-type RJ-11 modular jack receptacle on each end of emitter |

| Regulation | Output and balance stability is achieved by independently regulating the ion emission current of each polarity at each ionizer |

| Timing | Precise timing (0-10 sec @ 0.1 sec revolution) generated by a local microcontroller; LEDs on each emitter indicate polarity of the ion emission |

| Operating Mode | Pulsed DC, Steady-state DC, or standby |

| Emitter Points | Emitter Points Single-crystal Silicon or machined Titanium; all emitter points are replaceable |

| Cleanliness | Single crystal Silicon ISO 14644-1 Class 1; Titanium ISO 14644-1 Class 3 (Fed. Std. 209e Class 1 or better) equivalent |

| Emitter Rods | 2.5,5,10,15,24,36, or 60 in. (6.4,12.7,253.4,38.1,61.0,91.4, or 152.4 cm) |

| Alarm | Alarm operates when ionizer is no longer able to maintain preset ion output level; visual alarm red LED in the middle of the ionizer chassis flashes at a high rate to distinguish it from the output indicators; optional audible alarm sounds at the 5520/5580 controller when an alarm event occurs at any emitter; selectable with the 5571 handheld terminal |

| Preventative Maintenance |

Annual, semi-annual, or quarterly emitter point cleaning depending on process sensitivity and presence of AMCs in environment |

| Ozone | <0.005 ppm |

| EMI | Below background level |

| Operating Temp | 59-95ºF (15-35ºC), nominal |

| Humidity | 20-60% RH, non-condensing |

| Dimensions | 1.2H x 1.4W x 17.5L in. (3.1H x 3.6W x 44.5L cm) |

| Weight | 16.4 oz (465 grams) |

| Warranty | Two year limited warranty |

| Certifications | SEMI F47 Compliant  |

Ordering Information

| 91-5511C-xxSDLR | Emitter with titanium emitter points in 2.5,5,10,15,24,36, or 60 inch rod lengths |

| 91-5511U-xxSDLR | Emitter with silicon emitter points in 2.5,5,10,15,24,36, or 60 inch rod lengths |

| 91-5520R | Digital Controller, supports up to 20 ionizers |

| 91-5580R | Digital Controller, supports up to 80 ionizers |

| 91-5570 | Infrared Remote Controller |

| 91-5571 | Handheld Terminal for 5520/5580 Controller |

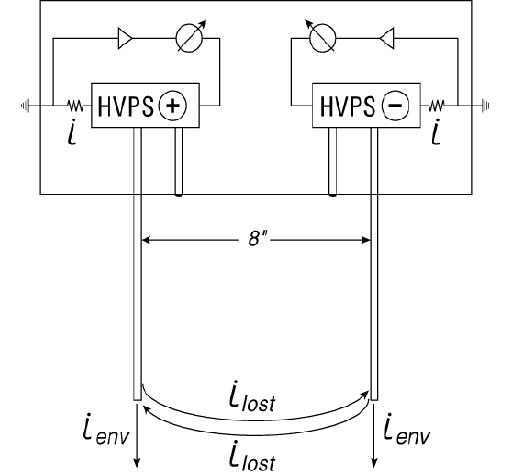

Simco-Ion design for maintaining stable ion current flow despite fluctuating environmental conditions, point erosion and point "aglomeration" (+HVPS Alarm - level set at factory).

Advanced Feedback Technology

The Model 5511 enhanced ion emitters provide an unprecedented level of control and protection, using a Self-Regulating Air Ionizing Apparatus sensing method. This feedback system assures the tightest feedback control available, unique in offering sensing, feedback and alarm capabilities at every emitter point in the system.

Simco-Ion uses a proprietary feedback circuit in the Model 5511 emitter. Each emitter has sensing circuits that accurately monitor the ion emission current from both the positive and negative emitter points. These circuits produce a signal proportional to the total ion production at each emitter point.

By monitoring and controlling every point of emission, the ionization system is able to consistently deliver highly accurate ion levels throughout an entire area. Each emitter can be fine-tuned to its local ionization requirements.

Digital Technology

Digital technology allows the flexibility to control and address the operational settings of the Model 5511 system including alarm sensitivity, ion output (down to percentage levels), ion pulse timing, and polling frequency. The Model 5511 offers flexible settings to fit any environment—any specification.