The Model 6422e-AC incorporates our auto-clean system that cleans the emitter points each time the unit power down. Automated cleaning reduces maintenance time, extends emitter point life and assures balanced performance.

Features:

- lsoStat® technology

- Small form factor available in steady-state DC ion emission blowers

- 24 VDC or 24 VAC input

- Facility Monitoring System (FMS) interface

- Operational failure alarm

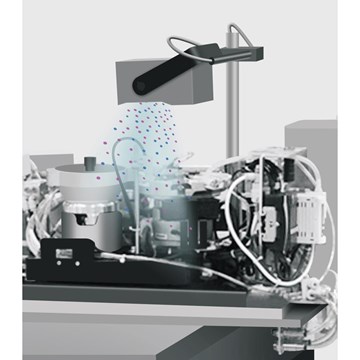

- U-bracket mounting

- Auto-Clean System

Benefits:

- Intrinsically balanced; no calibration needed

- Offers fast discharge times in confined areas

- Can connect directly to either equipment or wall power

- Faster response to failure with notification

- Provides visual notification of failures

- Flush or angled mounting means the blower will reach constrained spaces

- Reduced maintenance time, longer emitter point life, and assured balanced performance

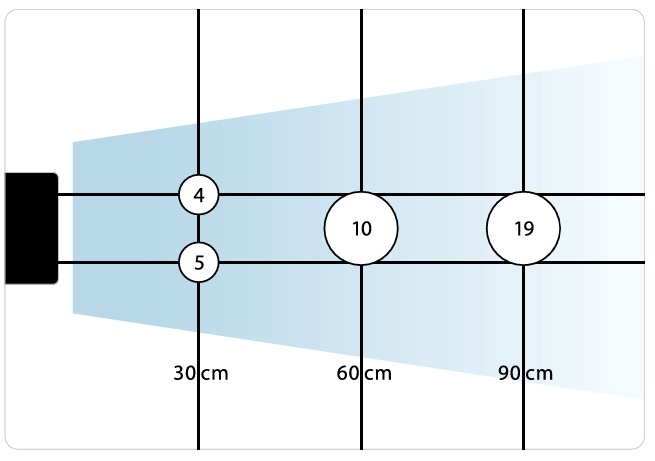

Typical Decay Time (sec)

Specifications:

| 6422e / 6422e-AC |

|

| Input Voltage | 24 VDC or 24 VAC, 50/60 Hz, 6 W max |

| Decay Time | < 4 s @ (1000 V to 100 V, 30cm, 24 VAC input) |

| Balance | ±20 V @ 30 cm |

| Technology | Steady-state DC |

| Emitter | Tungsten; internally shielded |

| Cleanroom Class | ISO 14644-1 Class 5 |

| Indicators | Power - Green; Fault - Red alarm |

| Connections | Terminal block for power and FMS fault signal output |

| Airflow (m3/min) | 0.65 (typ) |

| Ozone | <0.004 ppm (typ) |

| Operating Env. | 10 - 35ºC, 20 - 60% RH (non-condensing) |

| Mounting | U-bracket with factory installed |

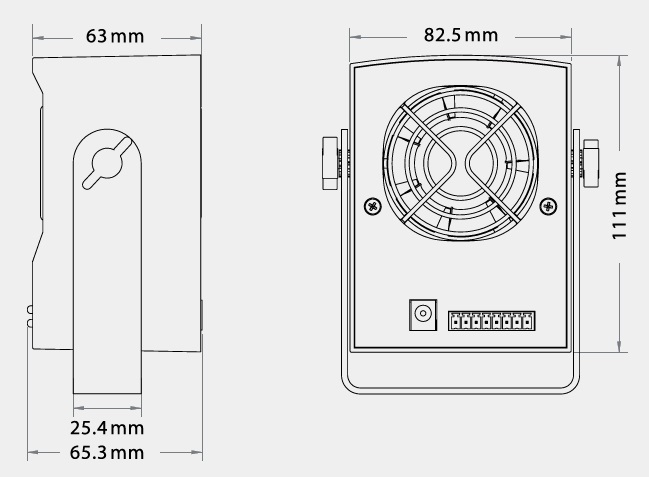

| Dimensions | With bracket : 12.5H x 10.4W x 6.3D cm; Without bracket : 11.1H x 8.3W x 6.3D cm |

| Weight | With bracket : 0.357kg; Without bracket : 0.314kg |

| Certifications |  |

Auto-Clean System

The Auto-Clean System features a brush mechanism that sweeps the emitter points when the blower is turned off and on, which significantly reduces the need for manual cleaning. Simco-Ion recommends activating the Auto-Clean System at least once a week. Cleaning schedules will vary depending on environmental conditions.

Enhanced Capabilities

An alarm LED on the front indicates a high voltage circuitry failure and a five-pin facility monitoring system (FMS) interface is on the rear of the blower, which provides a 4 - 20 mA current loop and relay output connection. With 24 VDC input connection, the FMS output is situated on a convenient terminal block, designed for easy integration.