RBS Detergent

产品查询Precision manufacturing involves surface preparation for bonding, coating or exposure to a special processing and environment that are highly sensitive to residues.

Key concerns in selecting detergent for precision manufacturing are efficiency in cleaning and non-use of volatile solvents, strong acids and other hazardous chemicals.

RBS aqueous detergents perform as well as or better than solvent cleaning agents in removing residues without the harmful environmental side effects.

RBS cleaning solutions are suitable for various high performance cleaning processes in precision manufacturing of glass, plastics, metal parts, electronics, ceramics, optics, medical devices.

It can be easily rinsed off residues free.

| Applications | RBS Product |

| Electronic, Semiconductors : Cleaning electronic component, circuit board, assemblies, screens, parts, ceramic insulators & components, silicon wafer, mold dies and cavities |

Mild alkaline / RBS IND 700, RBS IND 740 Manual, ultrasonic cleaning, soak 1-2%; 50-60°C |

| Glass, optic : Cleaning flat glass, optics & lenses, glass sheet, quartz |

Mild alkaline low foam / RBS IND 500, RBS IND 750 Part washer, power wash , spraying, brush system 1-2%; 45-60°C |

| Metal working : Cleaning stainless steel parts, chrome steel ... Low concentration, temperature and short contact time are recommended for soft metals. |

Heavy duty cleaning: Alkaline / RBS IND 710, RBS IND 743 Manual, soak, circulation 0.5-2%; 40-70°C |

| Plastic : Cleaning parts and surfaces made of resistant plastics. Not recommended for polycarbonate (PC). |

Alkaline low foam / RBS IND 755 spraying, part washer 0.5-1%; 45-60°C |

Removal of conductive residues, resins, rosins, fluxes, particulates, greases, oils, silicon oils, heavy fatty residues, cutting fluids, mold release agents, buffing compounds, waxes, polishing slurries, epoxy and organic residues.

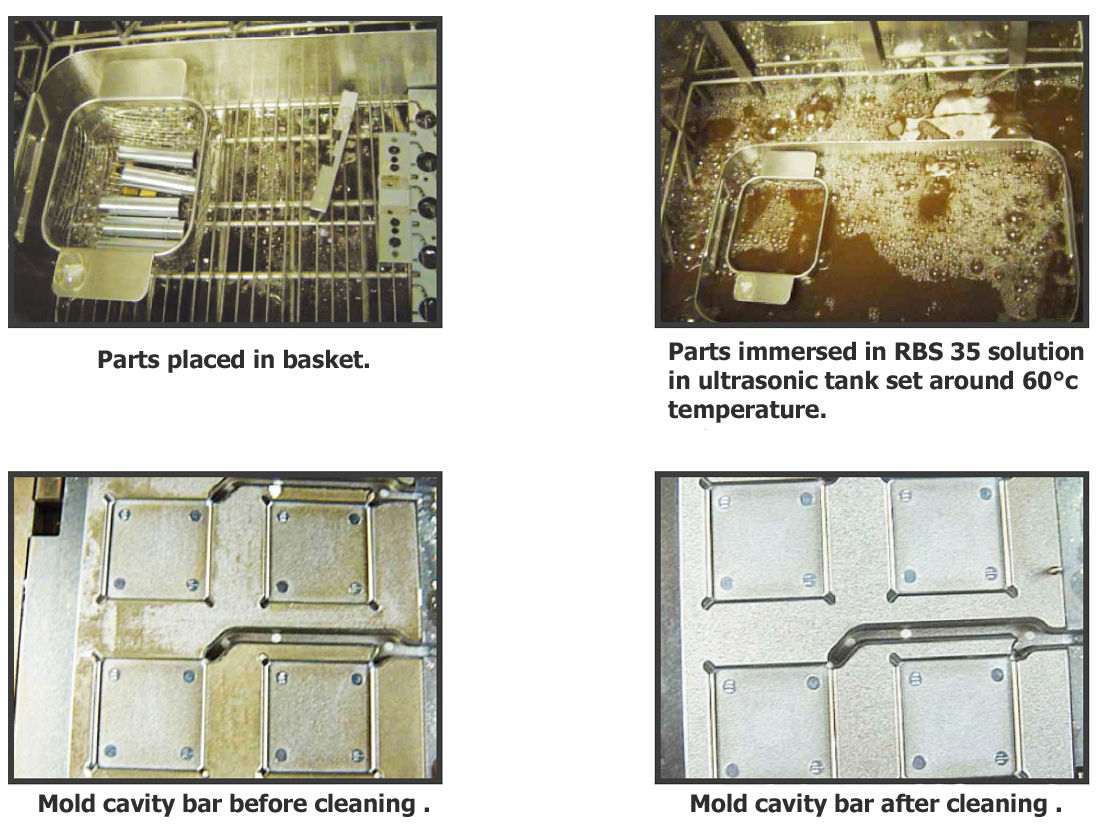

RBS 35 Concentrated Surfactant (for cleaning mold cavity bars)

RBS 35 is a concentrated cleaning agent which is foaming, alkaline and odorless. It is made up of anionic and nonionic surfactant, phosphates and polyphosphates, hydrates and chlorinated agents.

Directions for use:

a) Soaking

• Solution with water (recommended temperature of 50ºc- 70ºc)

Recommended concentration of 2% to 5%. (eg. 20ml to 1 litre of DI water.)

• Immerse work piece to be cleaned in solution completely for few minutes to 24 hours

(depending on solution temperature and tenacity of stain) .

• Rinse immediately with distilled or deionized water.

• Regular renewal of the solution ensures effective cleaning.

b) Machine Washing

• Automatic or ultrasonic machines

• Concentration of 2% to 5% is generally sufficient.