Carrier Tape Peel Back Force Tester (PBFT)

製品のお問い合わせ

GPD's Peel Back Force Tester with FORCEWARE™ software is being used to set peel back standards for the entire industry

Proven Peel Back Force Measurement

Supplying consistent SMT carrier packaging is critical for customers using SMT pick-and-place machines. Nothing will stop a production line faster than carrier cover tape that doesn’t peel back properly. The problem is difficult because tape cover adhesive varies widely from supplier to supplier.

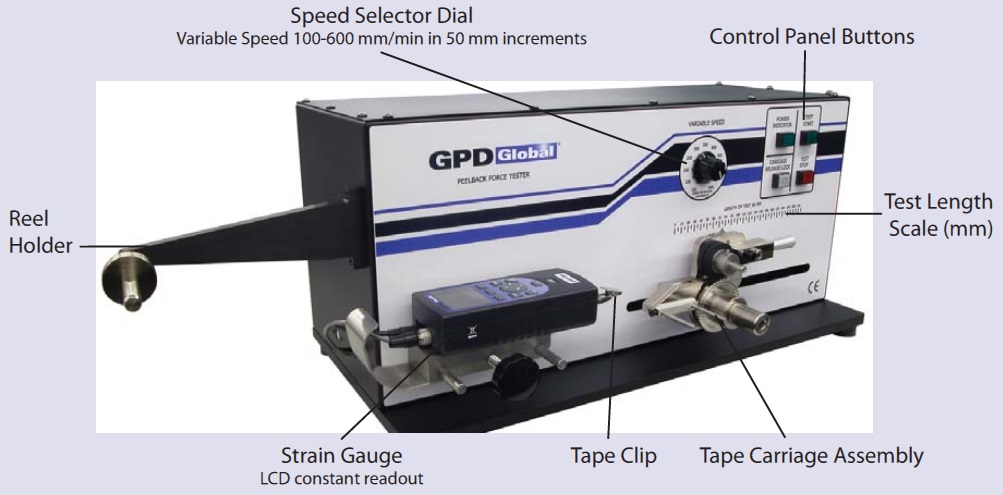

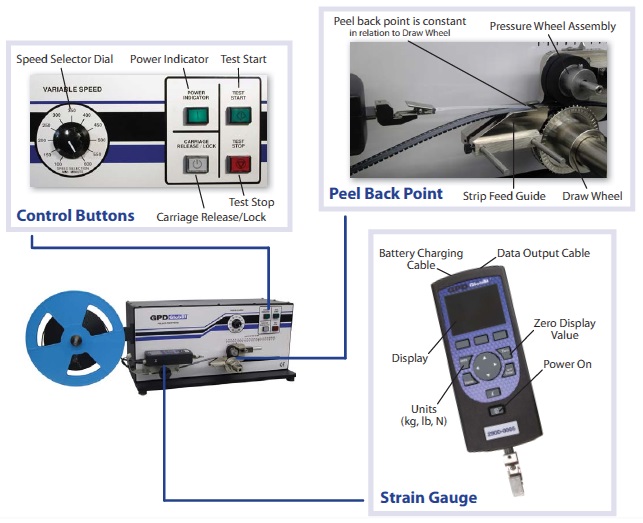

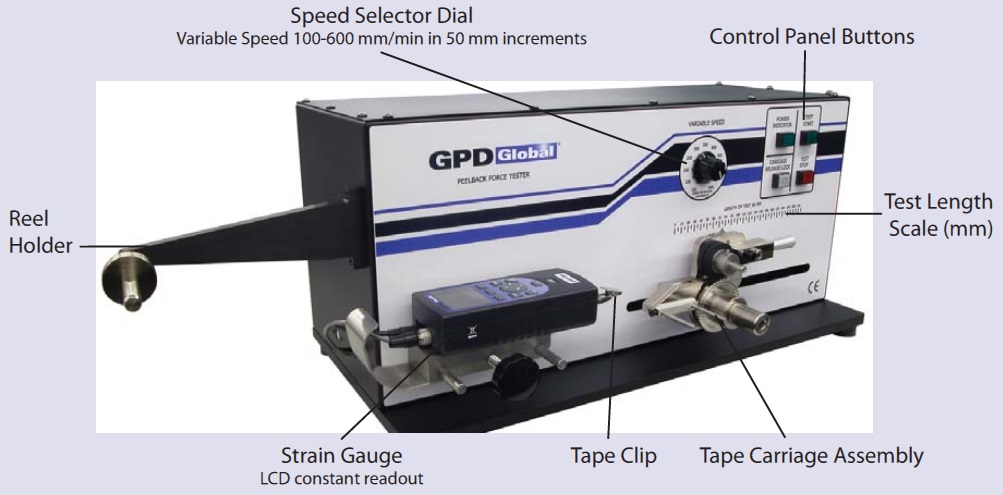

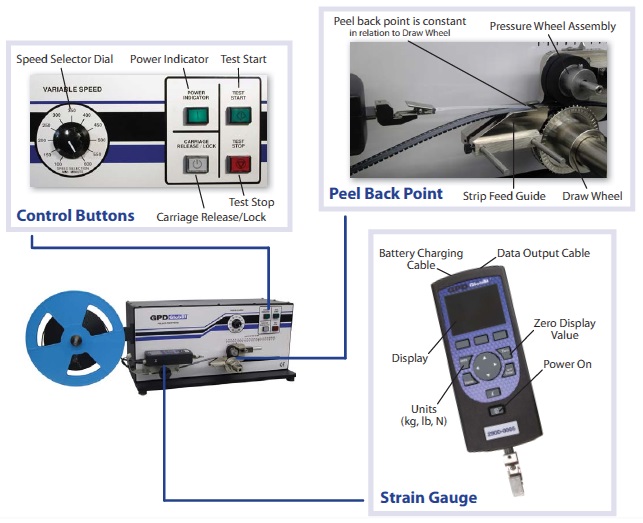

Installation and Set Up

Installation and Set Up

Configuration of the PBFT is quick and easy using the PBFT calibration dial and the strain gauge calibration screen.

Strain Gauge Verification Kit

(part no. PBT-107)

This optional kit makes it easy to verify strain gauge calibration and meet ISO requirements for calibrated equipment.

FORCEWare™ Software

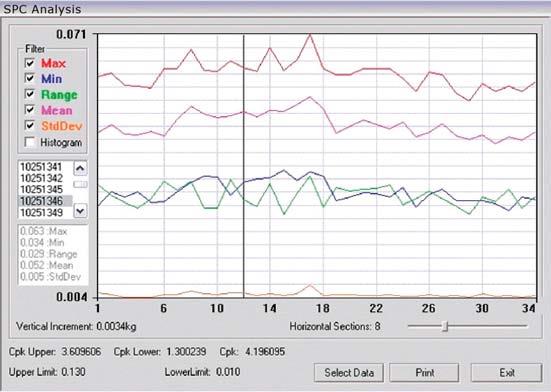

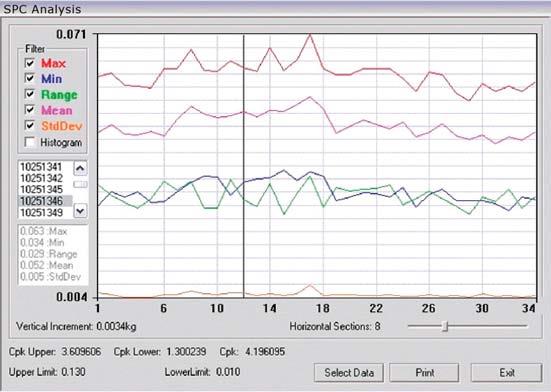

SPC Analysis

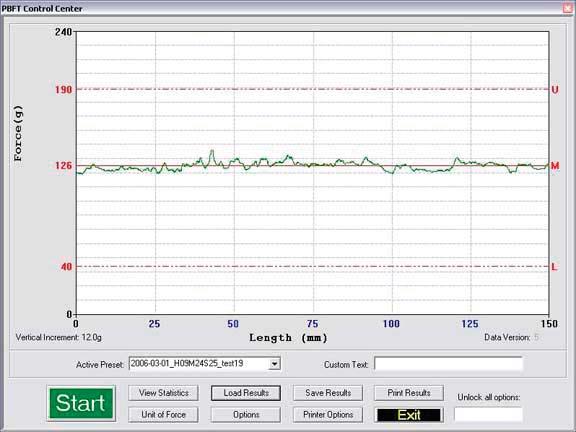

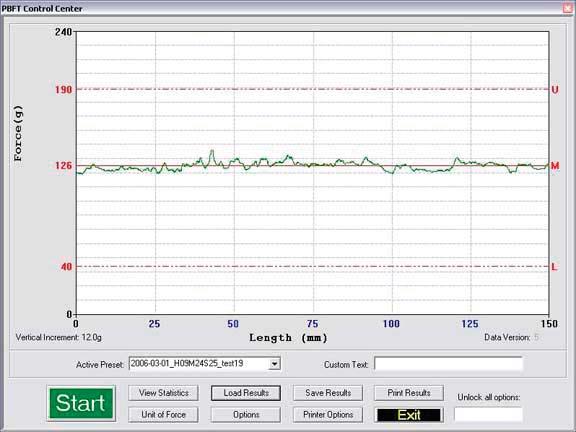

PBFT Control Center Window

The PBFT Control Center Window is used to define test parameters and unit of measure, run a test, and view, print, and save results. This window is also used to view and compare prior test results.

SPC User Creation Window

Test Graph

FORCEWare™ Software with SPC Software Package Runs on Windows 7 Pro, XP Pro, or Vista Pro / Ultimate

SPC Reports and Labels

SPC test results can be printed in SPC data, line graph, and label formats. The user can control the overall dimensions for all of these formats. User-defined print can also be added at the bottom of the SPC data and line graphs reports.

Previous Results Chart

This display is used to load previous results and past tests, in addition to generating additional results output.

S-Chart, X-Bar Chart, R Chart, and Cpk

Displays trends in spread of standard deviation, mean, range, and Cpk.

Features of the variable speed Peel Back Force Tester with FORCEWare™ software package

Build in Compliance With:

- IEC (Europe)

- EIA-J (Japan, Asia)

89/336/EEC EMC Directive

Laws relating to electrical magnetic compatibility

Applicable Standards:

EN 61010-1/2001

Safety requirements for electrical equipment for measurement control and laboratory use

EN 61326: 1998

Electrical equipment for measurement, control, and laboratory use. EMC requirements

DESKTOP or NOTEBOOK Capability

Model PBFTVS.USB700 includes a Tape Peel Back Force Tester with GPD Gloabal's FORCEWare™ software and SPC for Windows 7 Pro, XP Pro, or Vista Pro/ Ultimate for use on a desktop or notebook computer utilizing USB specification 2.0.

Specifications:

Proven Peel Back Force Measurement

Supplying consistent SMT carrier packaging is critical for customers using SMT pick-and-place machines. Nothing will stop a production line faster than carrier cover tape that doesn’t peel back properly. The problem is difficult because tape cover adhesive varies widely from supplier to supplier.

In short, correctly measuring, setting up, recording, and then analyzing carrier tape peel back force is a critical production step. That’s why you need GPD’s Peel Back Force Tester (PBFT) with FORCEWare™ software. This is the equipment judged so good it was used to set the peel back force standard for the entire industry.

Configuration of the PBFT is quick and easy using the PBFT calibration dial and the strain gauge calibration screen.

Strain Gauge Verification Kit

(part no. PBT-107)

This optional kit makes it easy to verify strain gauge calibration and meet ISO requirements for calibrated equipment.

FORCEWare™ Software

FORCEWare™ software allows the user to see, analyze, and record minimums, maximums, and average peel back force and speed, as well as standard deviation. GPD Global’s FORCEWare™ Software with comprehensive SPC Software Package makes testing and evaluation quick, easy, and accurate.

When sufficient SPC data has accumulated, it can be analyzed with any of the various window interfaces shown in the samples here. All you have to do is select the file to be analyzed, a data range, and the type of graph desired. Then simply print out or display the output.

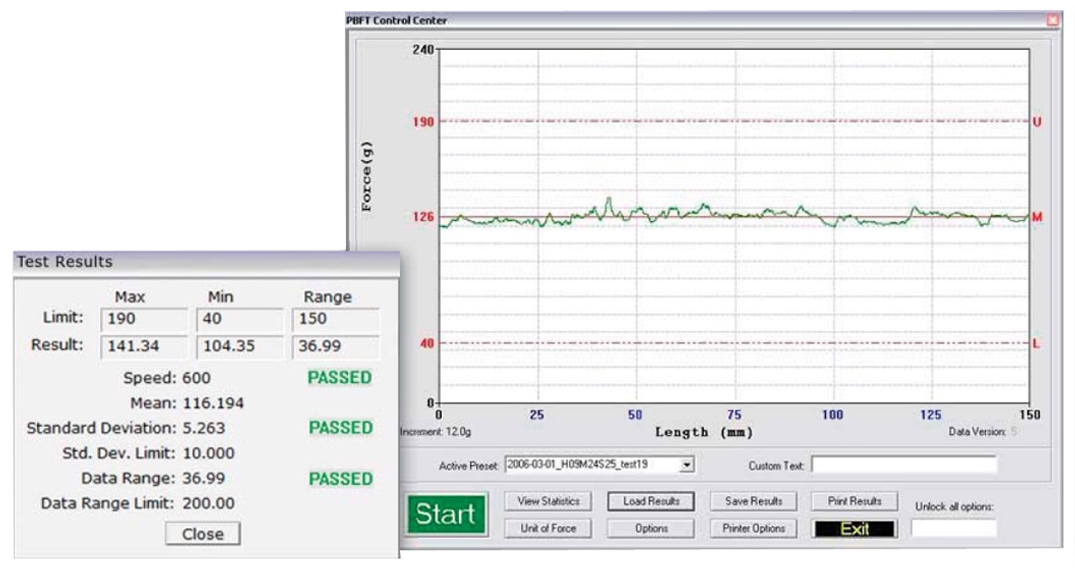

PBFT Control Center Window

The PBFT Control Center Window is used to define test parameters and unit of measure, run a test, and view, print, and save results. This window is also used to view and compare prior test results.

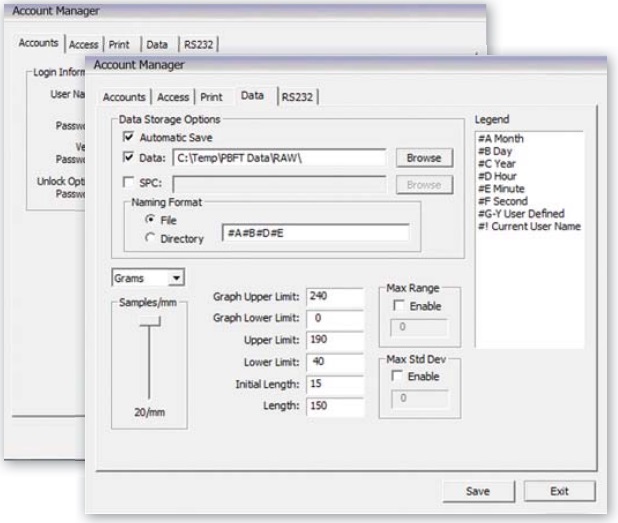

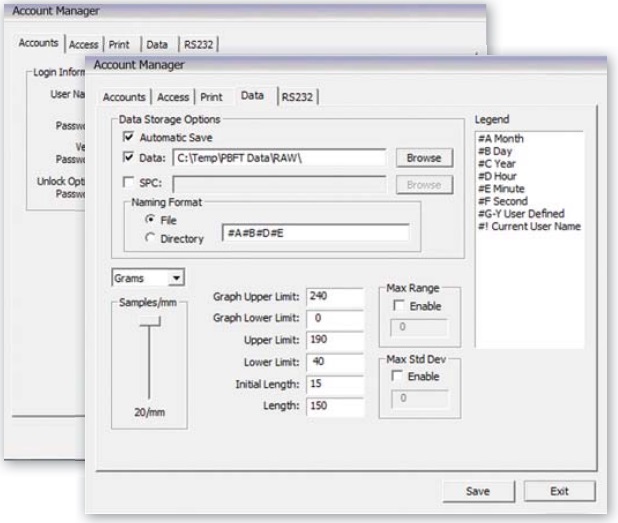

SPC User Creation Window

In addition to generating SPC data reports, the operator can also create separate log-in accounts, as well as implementing vendor defaults. Security features prevent unauthorized tampering.

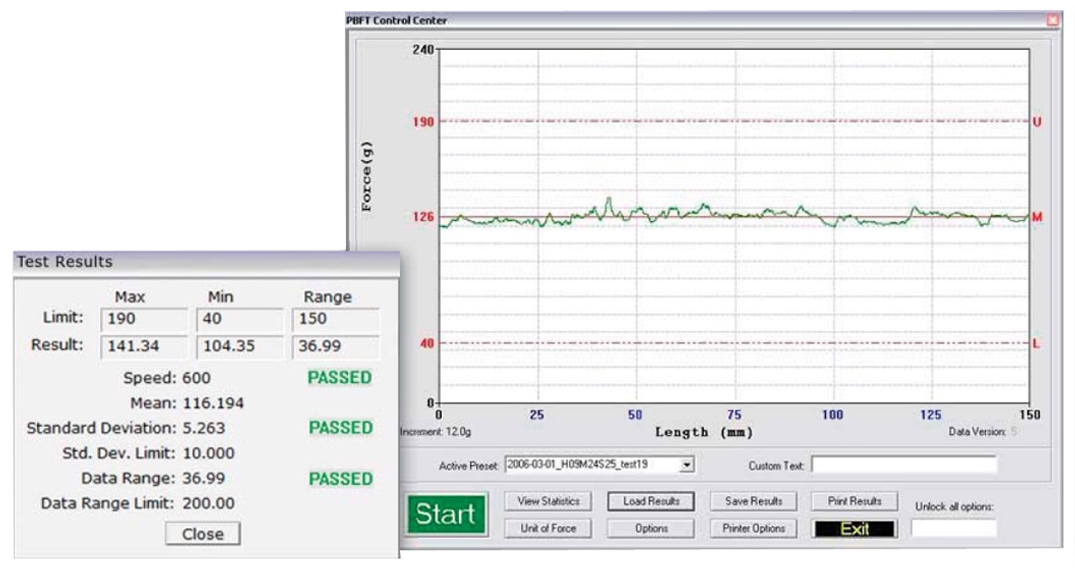

Test Graph

When a peel back force test begins, its progress displays on the test graph. Upon test completion, specific and summary data are displayed in a Test Results window. Many different graph forms can then be generated.

Current Results Chart

Display complete results of test. Results can be saved and reviewed.

Now the most accurate method of testing is also the easiest and fastest. With easy to use, point-and-click windows, initial set up is a breeze, and calibration routines for both speed and force are practically automatic. SPC analysis allows the operator to select the files to be analyzed, and pick the appropriate analysis tools. Analysis, and all management results can be printed out for further study or distribution.

- Simplified calibration routine for speed and force

- Selectable sampling rate

- Bright, clear, easy-to-read screens

- Large storage capability for test data, test graphics, and SPC data

SPC Reports and Labels

SPC test results can be printed in SPC data, line graph, and label formats. The user can control the overall dimensions for all of these formats. User-defined print can also be added at the bottom of the SPC data and line graphs reports.

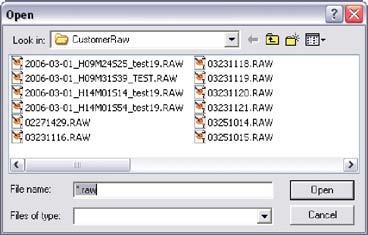

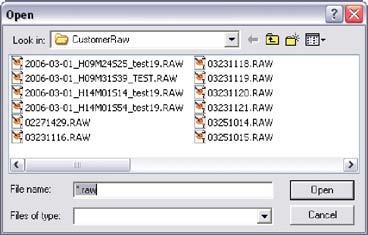

Previous Results Chart

This display is used to load previous results and past tests, in addition to generating additional results output.

S-Chart, X-Bar Chart, R Chart, and Cpk

Displays trends in spread of standard deviation, mean, range, and Cpk.

Features of the variable speed Peel Back Force Tester with FORCEWare™ software package

Build in Compliance With:

- IEC (Europe)

- EIA-J (Japan, Asia)

- EIA (North America): EIA-481-1, EIA-481-2, EIA-481-3

- European CE Safety Standards

Applicable Directives:

2006/95/EC Low Voltage Directive

Laws for electrical equipment within certain voltage limits

- European CE Safety Standards

Applicable Directives:

2006/95/EC Low Voltage Directive

Laws for electrical equipment within certain voltage limits

Laws relating to electrical magnetic compatibility

Applicable Standards:

EN 61010-1/2001

Safety requirements for electrical equipment for measurement control and laboratory use

EN 61326: 1998

Electrical equipment for measurement, control, and laboratory use. EMC requirements

DESKTOP or NOTEBOOK Capability

Model PBFTVS.USB700 includes a Tape Peel Back Force Tester with GPD Gloabal's FORCEWare™ software and SPC for Windows 7 Pro, XP Pro, or Vista Pro/ Ultimate for use on a desktop or notebook computer utilizing USB specification 2.0.

Specifications:

| Peel Back |

Force Measuring Range | 0 - 250 grams |

| Speed | 100 - 600± 5mm/minute in 50 mm increments | |

| Angle | 160 - 180 degrees | |

| Accuracy after Calibration | ± 3% | |

| Tape | Widths Accepted (mm) | 8,12,16,24,32,44, & 56 (optional 8 to 120 mm) |

| Materials Accepted | Plastic, Paper, Metal | |

| Configurations | Single or Dual Sprocket | |

| Power | AC Input Voltage | 100 VAC - 240 VAC |

| AC Frequency | 50/60 Hz | |

| Consumption | 60 watts maximum | |

| Fuses, Input power module | 1 amp, 250 volts | |

| Fuse, Power supply | 2 amps, 250 volts | |

| Physical | Dimensions | 12.5"H x 14.5"W x 29.0"D (31.8H cm x 36.8W cm x 73.7D cm) |

| Weight (approximate) | 68 lbs (30.8kg) | |

| Strain Gauge | Accuracy | ± 0.25% of full scale |

| Data Sampling Rate | Up to 20 samples per second, selectable from FORCEWare™ Software | |

| Battery life (approximate) | 30 hours, continuous use (strain gauge is normally plugged into the PBFT | |

| Certification | Calibration norms comply with ISO 10012 and ANSI Z540-1 Capacity is 2 lbf x 0.001 lbf with accuracy limits at ±0.25% of full scale ±1 LSC |

|

| FORCEWare™ Software |

Test Range -SPC Analysis | User-defined range |

| Test Range-Data Collection | Uses minimum/maximum limits of first file in selected data set | |

| Print Options | SPC data, Label format, Line Graph format |

Customer-Provided Computer Requirements:

| Computer | Dekstop or Notebook (minimum requirements are dictated by the operating system in use), CD-ROM drive, and 1 available USB 2.0 port |

| Operating System | Microsoft Windows 7 Pro, Windows XP Pro, or Windows Vista Pro / Ultimate |

| Memory | Minimum RAM is dictated by the operating system in use |

| Monitor | Minimum monitor is dictated by the operating system in use |

| Printer | Recommended: any printer configured for and supported by Microsoft systems |